Optimize Your Electronics Using Membrane Switch for Long-Lasting Results

Optimize Your Electronics Using Membrane Switch for Long-Lasting Results

Blog Article

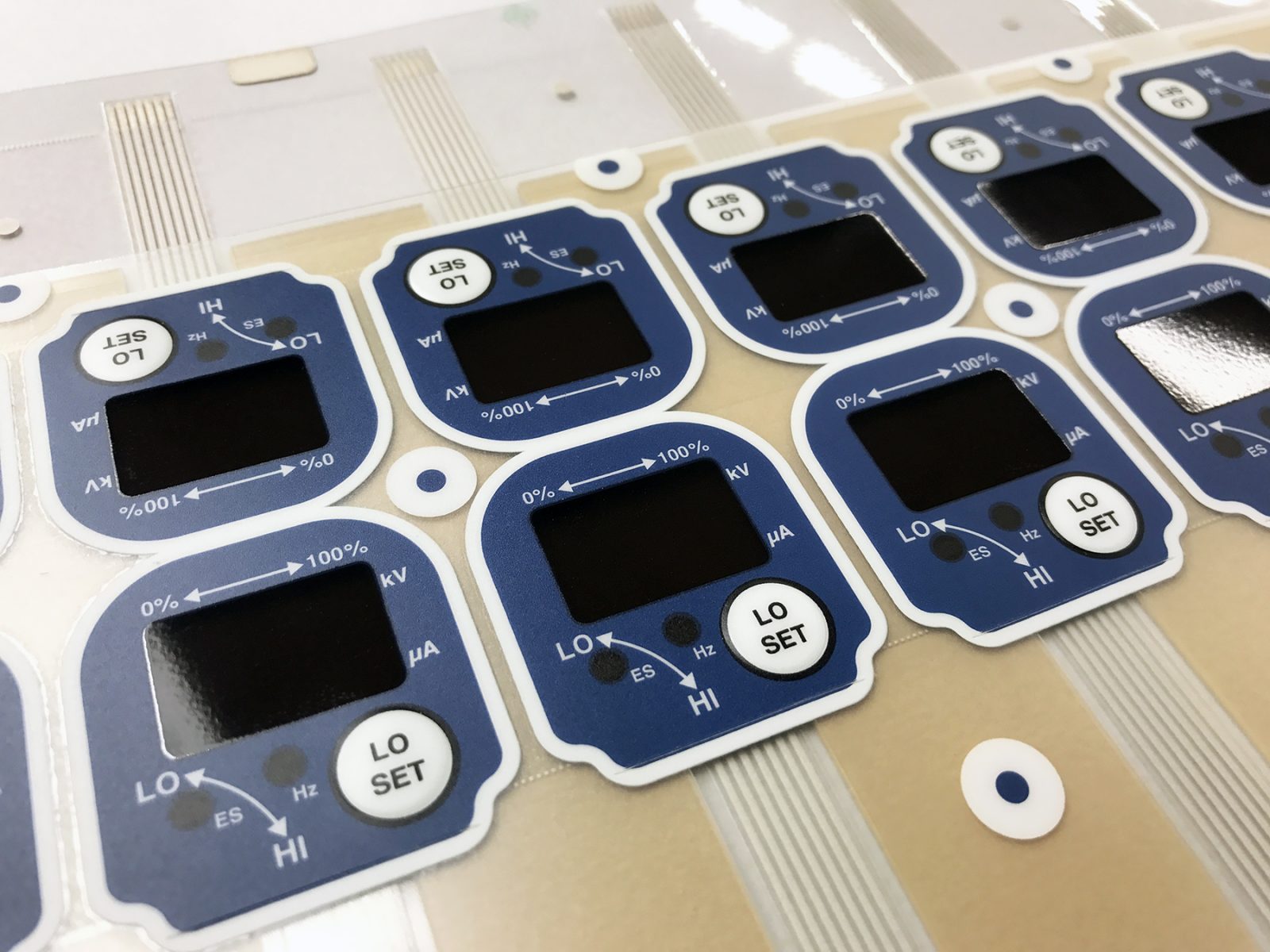

Discover the Versatile Use Membrane Switch in Modern Electronic Devices

In the world of modern-day electronic devices, the application of membrane switches is incredibly substantial, spanning from smooth customer gadgets to critical medical gadgets. These thin, adaptable interfaces not only improve tool procedure with their tactile responsiveness yet additionally significantly boost resilience by standing up to environmental dangers like wetness and dirt. As markets continue to evolve, the integration of membrane layer switches in equipment design is essential, promising not just to satisfy yet go beyond the rigorous demands of both capability and aesthetic allure. Discover a lot more about how these components are shaping the future of innovation.

Exploring the Duty of Membrane Changes in Consumer Electronic Devices

Why are membrane switches so prevalent in customer electronics? The response hinges on their special mix of price, adaptability, and dependability. Membrane layer buttons are affordable to produce, making them an appealing option for high-volume manufacturing common in customer electronic devices. Their building, featuring a thin, versatile layer that can conveniently be incorporated right into various tools, allows for smooth, compact item layouts.

Moreover, these switches are recognized for their longevity and reduced upkeep. From microwave stoves to remote controls, membrane switches provide a useful, easy to use interface that sustains the vibrant nature of customer electronics.

Membrane Layer Switches in Medical Devices: Enhancing Interface

Membrane buttons additionally play a significant role in the realm of clinical tools, where they improve interface with their distinct benefits. These switches are especially valued for their reliability and convenience of sanitation, important in medical care settings where cleanliness is critical. The smooth, closed surface area of membrane changes allows for easy disinfection, lessening the danger of contamination and spread of pathogens. Moreover, their design adaptability accommodates the aesthetic and ergonomic needs of medical equipment, making gadgets a lot more user-friendly and accessible for health care professionals.

Membrane buttons right here also add to the sturdiness of medical devices. Their resistance to pollutants and fluids ensures that vital devices remains functional in various clinical setups, consisting of surgical treatments where exposure to fluids prevails. This toughness, paired with tactile comments and inconspicuous style, makes membrane switches an important element in improving the effectiveness and security of clinical tool user interfaces.

The Effect of Membrane Layer Activates Industrial Tools Layout

In the realm of commercial equipment style, the consolidation of membrane layer buttons has noted a substantial advancement. These buttons have transformed how producers come look at this site close to interface performances, using a mix of resilience and convenience that is necessary in harsh settings. The slim account of membrane switches over permits even more portable equipment styles, while their resistance to water, dirt, and chemical impurities read this makes them optimal for commercial settings. This adaptability has helped with the growth of tools that is not only much more durable yet also less complicated to preserve and tidy, thereby decreasing downtime and functional expenses.

Furthermore, the customizability of membrane switches over enables designers to incorporate particular tactile feedback and visual overlays that enhance the user experience and boost effectiveness. This integration supports drivers in attaining accuracy control over complex equipment. The total impact is a substantial improvement in the capability, dependability, and user-friendliness of industrial equipment, straightening with the increasing needs for technical advancement and operational efficiency in contemporary industries.

Conclusion

Membrane buttons have reinvented contemporary electronics, using smooth, long lasting, and customizable interfaces throughout different markets. This innovation not only satisfies the demanding conditions of various fields however also substantially boosts customer experience, making membrane layer switches a foundation of contemporary electronic style.

In the realm of modern electronic devices, the application of membrane buttons is extremely considerable, extending from smooth consumer devices to important clinical gadgets.Why are membrane layer changes so common in customer electronics? Membrane switches are economical to make, making them an eye-catching option for high-volume production common in consumer electronic devices. From microwave ovens to remote controls, membrane layer switches supply a practical, easy to use interface that supports the vibrant nature of consumer electronic devices.

Report this page